The wheel has been around since about 4000 BCE (Bulliet, 2016). The first wheels used for transportation may have derived from potters’ wheels used for moulding cups and bowls. Some early wheels were made of stone, but these were soon replaced by wood which was lighter and faster. Around 3000 BCE spokes were invented, and for several thousand years fast-moving chariots with spoked wheels often decided ancient battles.

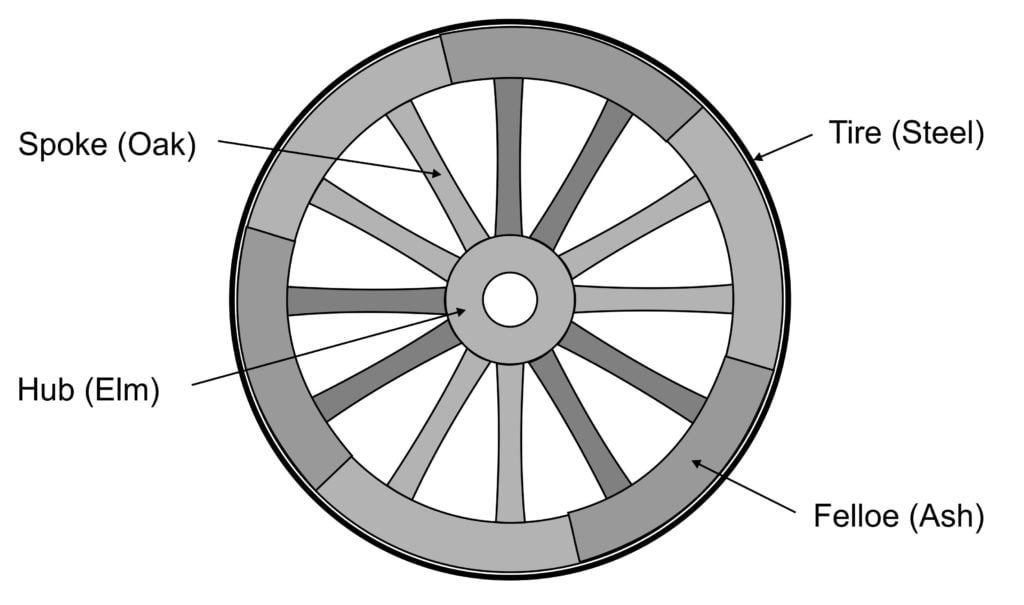

By the middle of the nineteenth century wooden wheels for carts and carriages had become fully developed (see figure). The rim was made by bending ash to form curved felloes. These were attached to the hub by strong oak spokes, and held in place by a steel tire.

In the last two hundred years the wheel has changed dramatically. Some changes have made the wheels more efficient (working well) and some made them more attractive (looking lovely). The forces driving the changes are thus similar to those that occur during evolution with its survival of the fittest and its sexual selection. However, wheel innovation is controlled by human design rather than random mutation, and the changes have occurred much more rapidly. And, as in evolution, some innovations do not survive: hubcaps and whitewall tires have become extinct.

In the last two hundred years the wheel has changed dramatically. Some changes have made the wheels more efficient (working well) and some made them more attractive (looking lovely). The forces driving the changes are thus similar to those that occur during evolution with its survival of the fittest and its sexual selection. However, wheel innovation is controlled by human design rather than random mutation, and the changes have occurred much more rapidly. And, as in evolution, some innovations do not survive: hubcaps and whitewall tires have become extinct.

Bicycles

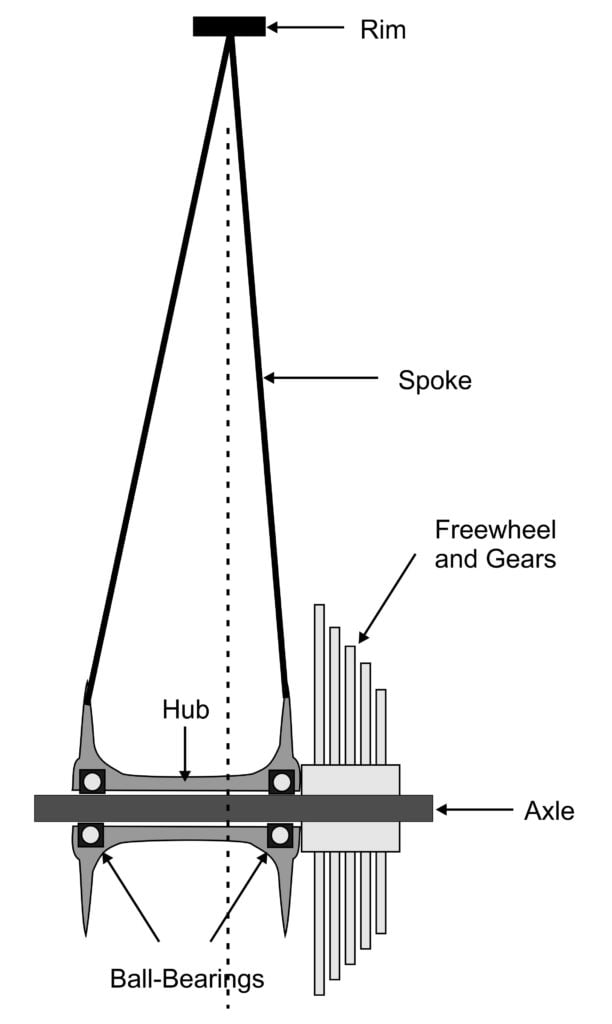

The new velocipedes (after 1820) and pedal-driven bicycles (after 1860) were powered by human beings rather than horses or oxen. This forced the development of lightweight wheels (Brandt, 1993; Herlihy, 2004). The first change was to make spokes of wire rather than wood. Initially these wires were arrayed radially from the hub to the rim. Spokes generally alternated between the two sides of the hub, giving the wheel a triangular cross-section, and thereby increasing the wheel resistance to compression (illustrated on the right). When a free-wheel system (invented in 1869 by William van Anden) was added to the rear wheel, the length of the spokes on the side of the free-wheel was shortened to maintain the wheel’s balance. This was called “dishing” the wheel, i.e. making it more like a dish than a plate. Ball-bearings were first used to facilitate the rotation of the bicycle wheel around the fixed axle in 1869.

The new velocipedes (after 1820) and pedal-driven bicycles (after 1860) were powered by human beings rather than horses or oxen. This forced the development of lightweight wheels (Brandt, 1993; Herlihy, 2004). The first change was to make spokes of wire rather than wood. Initially these wires were arrayed radially from the hub to the rim. Spokes generally alternated between the two sides of the hub, giving the wheel a triangular cross-section, and thereby increasing the wheel resistance to compression (illustrated on the right). When a free-wheel system (invented in 1869 by William van Anden) was added to the rear wheel, the length of the spokes on the side of the free-wheel was shortened to maintain the wheel’s balance. This was called “dishing” the wheel, i.e. making it more like a dish than a plate. Ball-bearings were first used to facilitate the rotation of the bicycle wheel around the fixed axle in 1869.

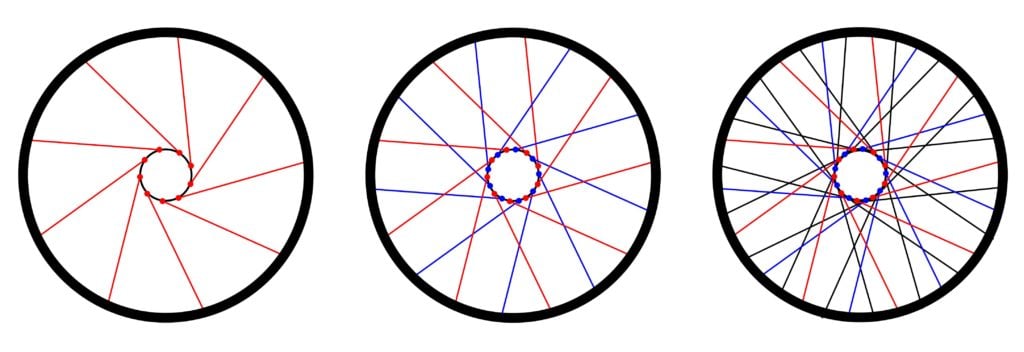

In 1874, John Kemp Starley invented a tangential approach to lacing the spokes of a wheel. The spokes were attached to the hub at an angle and crossed over each other on their way to the rim. This improved the ability of the wheel to resist the rotational forces (torque) involved when changing speed. Various levels of cross-over (from 1 to 4) are possible. Typical road bikes have 3-cross (3X) spokes. The spoke crosses another almost immediately upon leaving the hub, a second about an inch or so away from the hub, and a third about one third of the way out toward the rim. The following figure shows the lacing pattern of a 3-cross wheel (Litt, 2010; Brown & Allen, 2011). The left shows half the set of spokes from one side of the hub; the middle shows all the spokes on that side of the hub; the right shows all the 36 spokes from both sides of the hub.

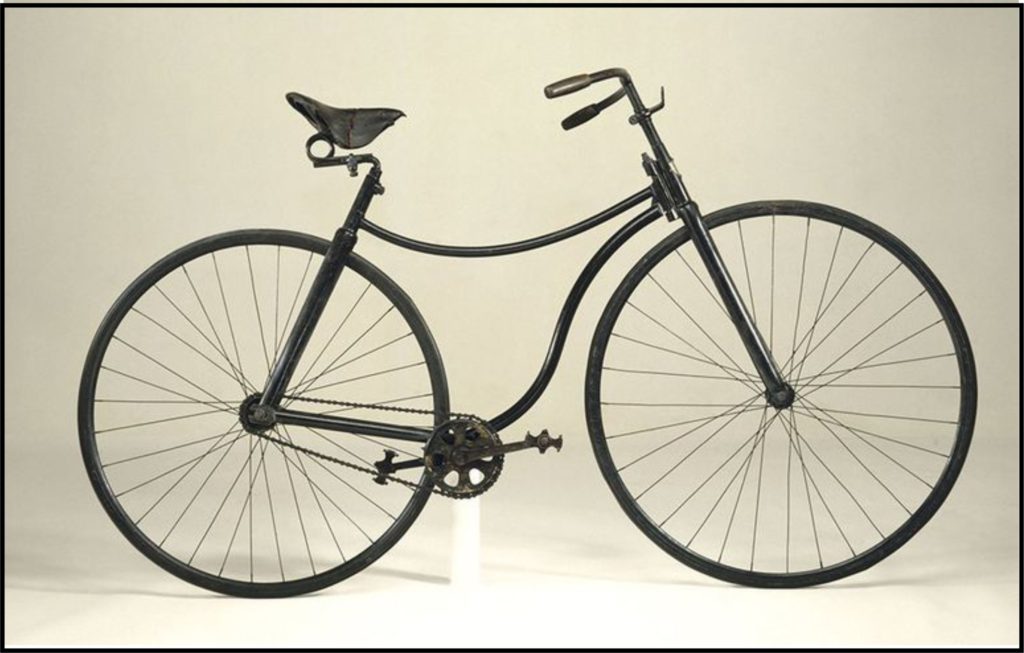

The 3-cross spoke pattern is present in the famous Rover Safety Bicycle marketed by Starley in the 1880s:

In 1889 John Boyd Dunlop made the first commercially successful pneumatic tires for bicycles. The idea had been patented some forty years before, but had not been followed into production.

Automobiles

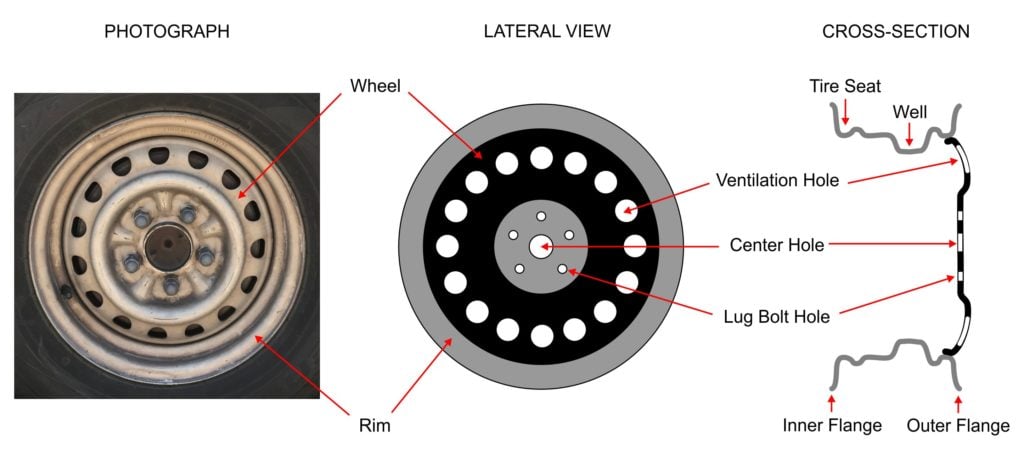

The first automobiles used bicycle wheels. As the automobile became heavier, the wheels had to become more robust. Although wire wheels were still used in racing cars and motorcycles, the most common automobile wheels were made of two pieces: a drum (barrel or rim) upon which the tire was mounted, and a wheel disk that was welded (or bolted) to the drum (see right). The joining occurred on the outer edge of the wheel. The complete wheel was therefore deeply dished to allow space for the brakes, which initially worked by pushing against the inside of the drum. Nowadays, these have largely been replaced by disk-brakes which operate on a disk attached to the axle within the dished wheel. A major difference between automobile and bicycle wheels is that the automobile wheel is fixed to the axle.

Initially the automobile wheel-disk was made of solid steel, but holes were soon inserted (Reif, 2011; Duffy, 2014). These lightened the wheels without significant loss in strength, and provided ventilation to prevent the brakes from over-heating. Unfortunately, the wheel was visually unattractive. To overcome this, whitewall tires were invented, but this still left a dark and dirty inner wheel. One could paint the wheel, but a more common approach was to cover the wheel with a shiny cover made of aluminum or plastic. This hubcap or wheel-cover also protected the lug-bolts that held the wheel to the axle-hub. The following figure shows examples of the exposed wheel (1 – unpainted, 2 – painted), two simple hubcaps (3 – baby moon; 4 – full moon), a simple decorative hubcap (5), and finally a very complicated decorative hubcap (6) imitating wire spokes (note the steel wheel behind the wires).

When a tire needed changing the hubcap had to be removed to access the lug bolts. The hubcap was therefore spring-clipped to the wheel so that it could be easily popped off with a tire-iron. Unfortunately, potholes and bumps often had the same effect, and hubcaps became a common sight at the edge of the road (see right). Businesses sprang up to collect and resell lost hubcaps. One way to prevent this was to fix the hubcap more permanently to the wheel and to leave holes to access the lug bolts. Ultimately this led to there being two wheels: the sturdy steel wheel that supported the rim and the light wheel-cover that made the wheel look more appealing.

When a tire needed changing the hubcap had to be removed to access the lug bolts. The hubcap was therefore spring-clipped to the wheel so that it could be easily popped off with a tire-iron. Unfortunately, potholes and bumps often had the same effect, and hubcaps became a common sight at the edge of the road (see right). Businesses sprang up to collect and resell lost hubcaps. One way to prevent this was to fix the hubcap more permanently to the wheel and to leave holes to access the lug bolts. Ultimately this led to there being two wheels: the sturdy steel wheel that supported the rim and the light wheel-cover that made the wheel look more appealing.

This redundancy can be prevented if the supporting wheel could be made more visually attractive (Newton, 2007). Then it would provide both the strength and the shine. The advent of new magnesium and aluminum alloys and improved casting techniques led to wheels that no longer needed to be covered to look good. The following illustration shows an early aluminum wheel (Style 5) from BMW with a mesh pattern that pays homage to wire-spokes (1), a classic Mercedes star wheel (3) and an elegantly simple alloy wheel from Lexus (3):

Recently the rim, spokes and center disk are typically forged in one piece. The following illustration compares an old two-piece welded steel wheel to two new one-piece forged wheels from Bayern and from Konig:

With the bright new wheel designs there is no longer need for whitewalls. Hubcaps are now restricted to the center hole of the wheel where they display the company logo. The most famous of these “center caps” is made by Rolls Royce to rotate in the opposite direction to the wheel, making the double-R legible at any speed.

Primes and Patterns

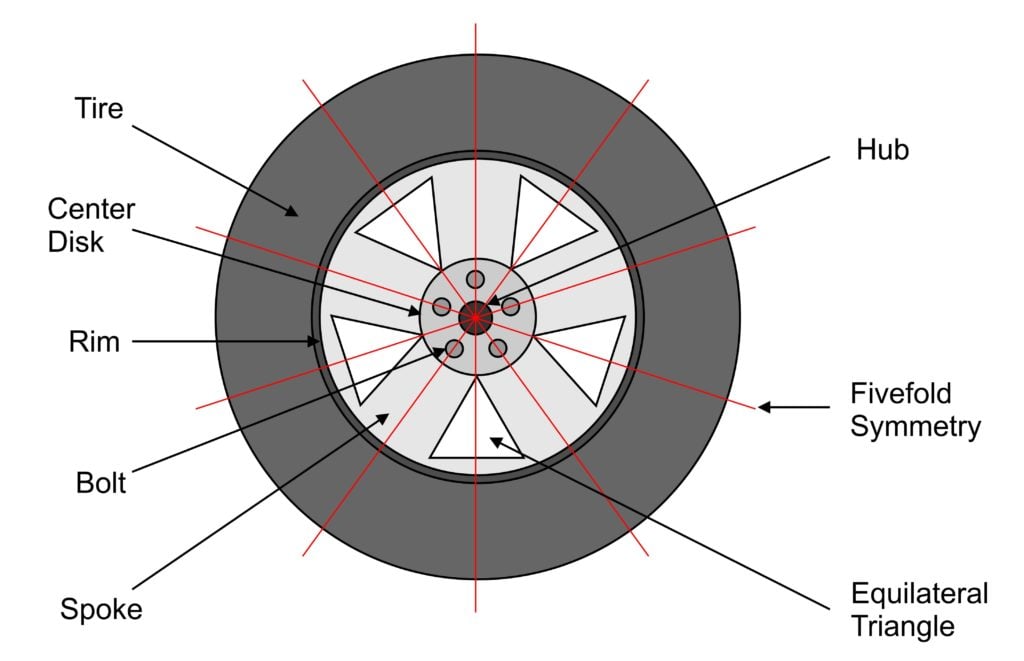

Most wheels on passenger cars are attached using 5 lug-bolts. Smaller cars can use 4 or even 3 and larger cars and SUVs often use 6. Fivefold symmetry makes it difficult to generate resonance vibrations between different parts of the wheel since 5 is a prime number. The other advantage is that the openings between the spokes approximate an equilateral triangle, the strongest triangle design. Five-sided shapes (pentagons and pentacles) are aesthetically pleasing, perhaps because they have some symmetry but not too much.

Although the spoke design is generally based on 5, the spokes may be paired or tripled, and spoke patterns based on 3 , 4, 6 or 7 are also possible (following illustration). The combination of 5 lug-bolts and 7 spokes seems to fulfil the idea of “prime” wheels.

With the new alloys and finishes, various patterns can be designed. Shiny surfaces can highlight the basic structure (1). Rotationally asymmetrical wheels (2) look like they are meant to go in one direction. This leads to the problem that the wheels on the two sides of the car want to go in opposite directions. On the right, the wheel from the Lexus (3) shows a pattern that alludes to the tangential spokes initially developed for bicycle wheels.

Envoi

Wheels have developed to satisfy both function and fashion. They are an essential part of both the operation and attractiveness of the modern bicycle and automobile. Wheels define a vehicle’s “street presence.”

References

Brandt, J. (1993). The bicycle wheel. 3rd Edition. Palo Alto, CA: Avocet.

Brown, S, (2008, revised by Allen, J., 2011) Wheelbuilding.

Bulliet, R. W. (2016). The wheel: Inventions & reinventions. New York: Columbia University Press.

Duffy, J. E. (2014). Modern automotive technology. Eighth Edition. Tinley Park, IL: Goodheart-Willcox.

Herlihy, D. V. (2004). Bicycle: The history. New Haven: Yale University Press.

Litt, S. (2010). Wheel Building.

Newton, R. (2007). Wheel and tire performance handbook. St. Paul, MN: Motorbooks.

Reif, K. (Ed.) (2011). Bosch Automotive Handbook. 8th Edition. Chichester, UK: John Wiley

Great perspective on the parallel between natural and technological evolution. The latter now being so fast that it now may drive the former. 🙂